M.C. coarse screen Process & Technology

Energy-saving process and Technology of M.C. coarse screen

Zhengzhou Leizhan improved and summarized a set of energy – saving process that apply to current OCC waste paper quality and paperboard requirements in continuous development of wrapping paper pulp making technology.

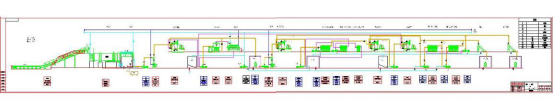

The LOCC T paper pulp flow chart of Hengfeng 300tons per 15hour.

Work principle of M.C. coarse screen

Firstly, Leizhan company adopts energy-saving and efficient drum breaking system, mild pulper reduce the repulping process on the secondary role of recycling fibers cut off. To ensure that the final paper targets, and also without destroying the physical dimensions of the impurities, in the pulping section will conduct a preliminary screening, remove light impurity in pulp of system. Reduce load of screening process and improve filtering effect , supporting has drum pulper system of BFW chain conveyor with stable and free maintenance, can realize the automatic control of cracking , guarantee the concentration of slurry and stability of yield.

Secondly, adopt coarse filter and fine filter screen of M.C. pressure screen can adopt to higher concentrations, reduce white water that diluted by slurry. Optimized rotor make configured the power for pressure screen lower but has higher efficiency.

Finally, supporting the use of high and low consistency cleaner and Tailings treatment equipment such as light slag separator, reject separator and so on that all use the best technology configurations and manufacturing precision, to ensure the entire pulp line running high efficiency, and the quality of final pulp product more cleaner. All the Total installed power of main equipments for this pulp line is about 1106KW, tons of energy for pulp is about 55.3KW.H, and the actual power consumption is about 41.4d/t (absolutely dry pulp).

All the stones together can have a solid foundation; we are looking forward to the future and full of hope. Leizhan company desire to cooperate with paper making enterprises home and abroad to create the wonder future and mutual benefit to reach a win-win situation.

Welcome

Leizhan paper pulp machine are mainly about pressure screen( M.C. pressure screen, Inflow pressure screen ), Drum Pulper VS D type Hydrapulper, Bale Opener, waste paper Chain Conveyor, Pulp Pump, Vertical Hydrapulper, Light Impurity Separator, Auto-cleaning Vibrating Screen, Reject Separator, refiner equipment, etc.

Leizhan Products

- Three Wires Cardboard Paper Machine

- Tissue Paper Machine Making Machine

- 4600 Low Weight High Strength Corrugated Paper Making Machine

- 4400/350 Triple Layer Liner Cardboard Paper Machine

- 4200 High Strength Corrugated Paper Making Machine

- 3800 Five-wire Coating Board Paper Machine

- 3700 Four Layer Cardboard Paper Machine

- Double Layer Kraft Paper Machine

- Slurry Approach System for Paper Making

- Kraft Liner/Testliner Paper Machine

- Drum Pulper Following Development Trend of Paper Industry

- High-speed Pulp Washing Machine

- ZG Series Drum Pulper

- ZDSD Series D Type Hydrapulper

- ZDSG Series High Consistency Hydrapulper

- ZDS Series Vertical Hydrapulper

- ZDSZ Series M.C. Hydrapulper

- SBJ Series Bales Breaker

- ZST Series Drum Screen

- Rope Cutter

- ZNS Series Mid Consistency Pressure Screen

- NLS Series Inflow Pressure Screen

- FQJ Series Light Impurity Separator

- PZ Series Reject Separator

- ZSK Series Auto-cleaning Vibrating Screen

- ZDFD Series Single Effect Fiber Separator

- ZDF Series Single Fiber Separator

- ZSF Series Hydrapurger

- UV Series Up Flow Pressure Screen

Paper Machinery Co., LTD.

E-mail: leizhanchina@gmail.com

Tel : +86-371-5512-9198

WhatsApp: +86-13783579051